No products

Prices are tax included

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

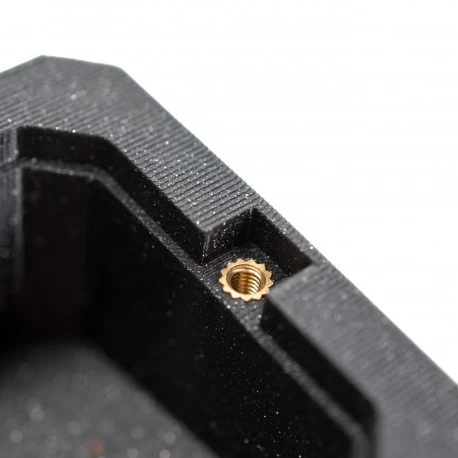

Heat-set threaded inserts created from brass provide a durable wear-resistant thread to a 3D printed part.

Threaded inserts by CNC Kitchen, community creator and youtuber.

Out of stock

60-030

Skriv din e-mail-adresse her, hvis du vil have besked når vi igen har denne vare på lager:

Notify me when available

Threaded inserts not only look great in 3D printed parts, but they also have a practical use. Everyone has had a device that was assembled with screws. After disassembling and reassembling it a few times, you realize that if the screws dug directly into the plastic, they won't hold anymore. Each time you screw the parts together, the material gets plastically deformed at the threads, which eventually leaves you with nothing but a ragged hole where nothing can grab. This is where thread inserts come into play. By melting them into your parts, they are positively bonded to the plastic and no longer move. The screws are now turned into durable and also low-friction brass and thus will last forever.

- PROTECT OUR ENVIRONMENT, 100% LEAD and CADMIUM FREE Brass alloy

- ORIGINAL CNC Kitchen threaded inserts for 3D printed parts (PLA, PETG, ABS, etc.),

- HIGHEST QUALITY, make your printed parts to professional products

- PRECISE CNC machined inserts made from high-quality Lead and Cadmium free alloy

- EASY INSTALLATION with a soldering iron. Installation temperature is the printing temperature +10 °C

Installation

You can install heat-set inserts by pushing them into the plastic with a soldering iron. The printed plastic will melt and reflow around the knurled external surface. This creates a secure bond between the insert and the plastic and ensures a strong pull-out resistance and torque-out rating. When preheating your soldering iron, use the print temperature for the specific filament that was used to print the plastic part increased by 10°C - 20°C.

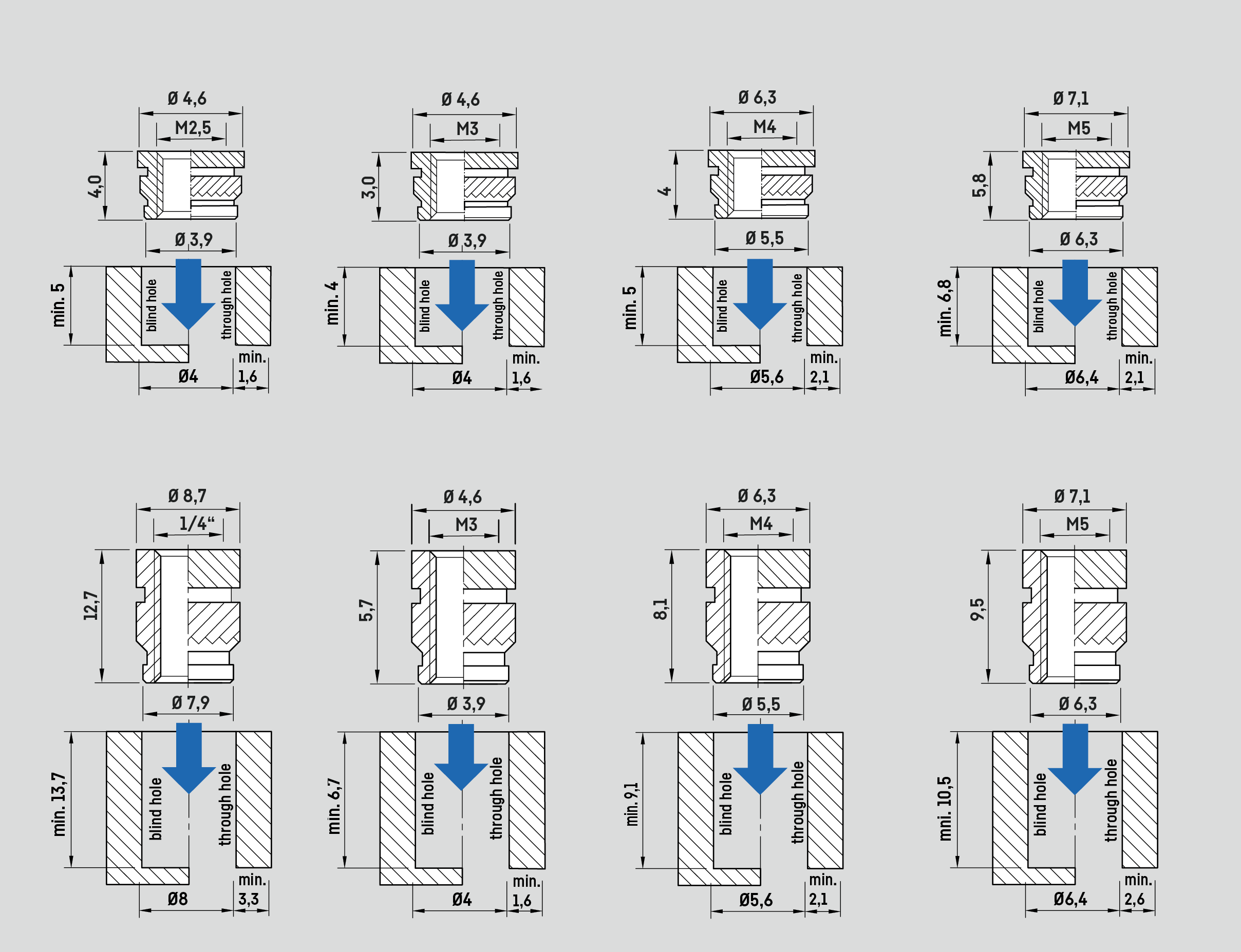

Use the drawing below to reference the ideal dimensions of holes for the insert. The hole should be just large enough so that the insert can be easily pushed in and that no burr remains under the insert after melting.

Specific package contents:

- Set standard: M3x5,7 mm (100x); M4x8,1 mm (50x); M5x9,5 mm (50x) pcs

- Set short: M3x3 mm (100x); M4x4 mm (50x); M5x5,8 mm (50x) pcs

- M2,5 standard (100x) pcs

- M3 standard (100x) pcs

- M3 short (100x) pcs

- M4 standard (50x) pcs

- M4 short (50x) pcs

- M5 standard (50x) pcs

- M5 short (50x) pcs

- 1/4" (20x) pcs

| Spare Parts Category | NOZZLE |